Carbon

Type of resources

Topics

Keywords

Contact for the resource

Provided by

Years

Formats

Representation types

Update frequencies

Resolution

-

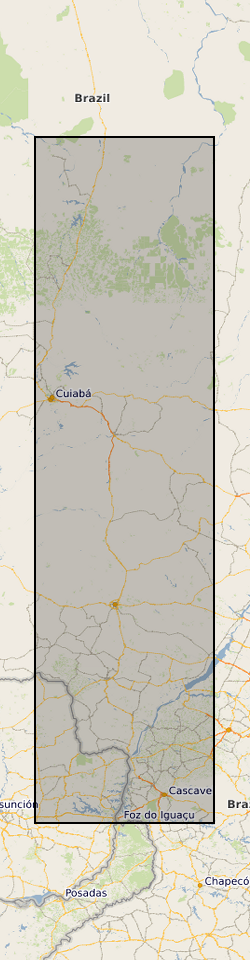

A dataset of DOC and DBC concentrations from 78 sampling locations in South American rivers (surface waters).

-

The potential for leakage of CO2 from a storage reservoir into the overlying marine sediments and into the water column and the impacts on benthic ecosystems are major challenges associated with Carbon Capture and Storage (CCS) in subseafloor reservoirs. A field-scale controlled CO2 release experiment was conducted in shallow, unconsolidated marine sediments. Changes were monitored of the chemical composition of the sediments and overlying water column before, during and up to 1 year after the 37-day long CO2 release from May 2012 to May 2013 in Ardmucknish Bay. Meiofaunal samples were collected and meiofauna higher taxa and the nematodes species (where possible) were identified by Plymouth Marine Laboratory. This dataset was collected under the program QICS (Quantifying and monitoring environmental impacts of geological carbon storage) which was funded by the Natural Environment Research Council (NERC), with support from the Scottish Government. The results are contained in an Excel file. QICS project website: www.bgs.ac.uk/qics/home.html. This data is currently under embargo until publication of the dataset in research article (estimated end of 2015).

-

During 2010-11, as part of the Carbon Capture & Storage (CCS) Demonstration Competition process, E.ON undertook a Front End Engineering Design (FEED) study for the development of a commercial scale CCS demonstration plant at Kingsnorth in Kent, South East England. The study yielded invaluable knowledge and the resulting material is available for download here. This Key Knowledge Reference Book is the result of the early stages of a Front End Engineering and Design (FEED) study to add a post-combustion Carbon Capture and Storage (CCS) facility to a new supercritical coal fired power plant at Kingsnorth following the award of a FEED contract with the Department of Energy and Climate Change (DECC) in March 2010. This study constitutes the first phase of a 3-phase approach to FEED adopted by E.ON UK. The Kingsnorth CCS Project consists of two 800MW power generating units at Kingsnorth power station, a 300MW (net) post combustion carbon capture plant integrated into the power plant with associated dehydration and compression facilities, a 36inch pipeline for transportation of CO2 to the Hewett gas field in the southern North Sea and a new platform at this field with associated injection facilities and wells. The Key Knowledge Reference Book is publicly available to all CCS project developers and other interested parties to ensure the lessons learned from this FEED are disseminated as widely as possible to advance the roll-out of Carbon Capture and Storage. This Key Knowledge Reference Book comprises information provided in the following structure: Chapter: 1 Executive Summary. 2 Content. 3 Table of Acronyms. 4 Project Design. 5 Technical Design - Carbon Capture and Compression Plant. 6 Technical Design - Pipeline and Platform. 7 Technical Design - Wells and Storage. 8 Health and Safety. 9 Environment and Consents. 10 Project Management Reports. Summary commentary on each of the chapters is provided to give both context to the information supplied and to pull out key areas of learning in each section. The Key Knowledge Reference Book is available for download and supporting materials for each chapter are available. Note this dataset is a duplicate of the reports held at the National Archive which can be found at the following link - http://webarchive.nationalarchives.gov.uk/20121217150421/http://decc.gov.uk/en/content/cms/emissions/ccs/ukccscomm_prog/feed/e_on_feed_/executive_summ/executive_summ.aspx

-

During 2010-11, as part of the Carbon Capture & Storage (CCS) Demonstration Competition process, E.ON undertook a Front End Engineering Design (FEED) study for the development of a commercial scale CCS demonstration plant at Kingsnorth in Kent, South East England. The study yielded invaluable knowledge and the resulting material is available for download here. This chapter presents the FEED stage Capture and Compression plant technical design. The 'Design Basis for CO2 Recovery Plant' lists the design parameters relating to the capture plant site, the flue gas to be treated, the utilities available, the required life and availability of the plant, and other constraints to be complied with in the capture plant, dehydration and compression design. The details of the processes of capture, compression, and dehydration are best visualised on the Process Flow Diagrams (PFDs) which show the process flows described above together with additional detail of coolers, pumps, and other plant items. Separate PFDs are provided for the capture plant, the compression plant, and the dehydration plant to show the complete flue gas and CO2 flows. Some of the key aspects of the technical design of the Capture and Compression plant are; There are two separate water circuits shown in the quencher with separate extractions of excess water. These have been separated because the recovered quench water is of good enough quality for re-use on the power station, whilst the deep FGD waste water is sent to the water treatment plant; Molecular sieves have been selected as the most appropriate equipment for dehydration of the CO2 prior to pipeline transportation; With the particular layout constraints of the Kingsnorth site, a split layout of the absorption and regeneration equipment is preferred over the compact layout. Further supporting documents for chapter 5 of the Key Knowledge Reference Book can be downloaded. Note this dataset is a duplicate of the reports held at the National Archive which can be found at the following link - http://webarchive.nationalarchives.gov.uk/20121217150421/http://decc.gov.uk/en/content/cms/emissions/ccs/ukccscomm_prog/feed/e_on_feed_/technical/technical.aspx

-

During 2010-11, as part of the Carbon Capture & Storage (CCS) Demonstration Competition process, E.ON undertook a Front End Engineering Design (FEED) study for the development of a commercial scale CCS demonstration plant at Kingsnorth in Kent, South East England. The study yielded invaluable knowledge and the resulting material is available for download here. This chapter contains design philosophy documents which were produced to ensure a common approach to the design of all aspects of the CCS project, addressing overall project lifecycle and the interface between the Carbon Capture Plant and the Power Station. Some of the key issues concerning the design and integration of a CCS development are: Power plants have been designed for many years to operate flexibly in response to the demands of the electricity network. The CCS plant technology is closer to process plant technology which is not usually designed for such flexible operation, and this will provide a key challenge during the detailed design process to provide the required flexibility of operation; Assessment of various cooling technologies for the power station and carbon capture plant shows that direct water cooling is the Best Available Technology in terms of Environmental Impact; Significant parts of the existing cooling water infrastructure can be re-used; There is potential to advantageously interface steam and cooling systems between the power plant and CCS plant; Venting, and the consequent cooling, of CO2 for pressure relief or operational reasons raises issues with lack of buoyancy and dispersion which require significant further work. Further supporting documents for chapter 4 of the Key Knowledge Reference Book can be downloaded. Note this dataset is a duplicate of the reports held at the National Archive which can be found at the following link - http://webarchive.nationalarchives.gov.uk/20121217150421/http://decc.gov.uk/en/content/cms/emissions/ccs/ukccscomm_prog/feed/e_on_feed_/project_design/project_design.aspx

-

In March 2010, the Scottish CCS (Carbon Capture & Storage) Consortium began an extensive Front End, Engineering and Design (FEED) study to assess what would be required from an engineering, commercial and regulatory, perspective in order to progress the CCS demonstration project at Longannet Power station in Scotland through to construction. The study yielded invaluable knowledge and the resulting material are available for download here. This chapter contains the output from many of the Project Management processes which control and report the progress of the FEED. The following commentary gives the reader a brief guide to the project management process or approach which has been used. FEED Programme: In order to scope out, control and report the FEED activity, a Work Breakdown Structure was developed. This structure had the following hierarchy - Level 1 - Chain Element; Level 2 - Phase; Level 3 - Discipline; Level 4 - Work Package (including Cost Time Resource definition); The programme is in the form of a fully resource loaded, logically linked network diagram. Risk Management: Throughout this FEED the management of risk was a key activity. This has helped inform and better understand the important risks faced by the project. This 'first of a kind' project saw a large number of new risks being identified, assessed, controlled and monitored during FEED. Project Cost Estimates: An estimating philosophy was established in FEED to set the standards for the estimates produced from across the project participants, including: To ensure a consistent approach in the collection, calculation and presentation of costs across all FEED Participants; To ensure that all likely project costs are identified and captured along with all associated details. A standard template was established for each participant to complete with the details of their section (i.e. Chain Element) of the cost estimate. The cost estimate was broadly consistent with Class 3/4 estimate as defined by AACE. Further supporting documents for chapter 10 of the Key Knowledge Reference Book can be downloaded. Note this dataset is a duplicate of the reports held at the National Archive which can be found at the following link - http://webarchive.nationalarchives.gov.uk/20121217150421/http://decc.gov.uk/en/content/cms/emissions/ccs/ukccscomm_prog/feed/scottish_power/abstract/abstract.aspx

-

During 2010-11, as part of the Carbon Capture & Storage (CCS) Demonstration Competition process, E.ON undertook a Front End Engineering Design (FEED) study for the development of a commercial scale CCS demonstration plant at Kingsnorth in Kent, South East England. The study yielded invaluable knowledge and the resulting material is available for download here. This chapter presents the results of studies into the undersea storage reservoir for CO2, in the Lower Bunter sandstone of the depleted Hewett natural gas field, the design recommendations for new wells and recommendations for abandonment of existing wells. The study addresses the following areas; Storage Reservoir integrity and capacity; Construction and completion of wells; CO2 properties and injectivity; Abandonment of existing and new wells; Monitoring; Hazard Identification (HAZID) and Risk Assessment. Some of the key aspects of the Wells and Storage technical design are; Wells that have already been abandoned using conventional methods pose a risk of future leakage to the surface and thereby compromising the integrity of the CO2 store; Data acquisition can be difficult: ensure that all required data sets are identified and make requests as early as possible to ensure quality data is obtained resistant standards; The CO2 equation of state and phase diagram is paramount in designing the injection process. Temperature and pressure of the CO2 must be carefully specified to avoid uncontrolled condensation or vaporisation; Many standard components and materials used in the offshore industry are suitable for use in CO2 flowing regime injection applications. Particular attention must be paid to corrosion resistance and longevity in a CO2 environment; For drilling injection wells into a depleted hydrocarbon reservoir, the principal challenge is drilling into low pore pressures, whilst minimising formation damage. Further supporting documents for Chapter 7 of the Key Knowledge Reference Book can be downloaded. Note this dataset is a duplicate of the reports held at the National Archive which can be found at the following link - http://webarchive.nationalarchives.gov.uk/20121217150421/http://decc.gov.uk/en/content/cms/emissions/ccs/ukccscomm_prog/feed/e_on_feed_/storage/storage.aspx

-

During 2010-11, as part of the Carbon Capture & Storage (CCS) Demonstration Competition process, E.ON undertook a Front End Engineering Design (FEED) study for the development of a commercial scale CCS demonstration plant at Kingsnorth in Kent, South East England. The study yielded invaluable knowledge and the resulting material is available for download here. This chapter contains the output from many of the Project Management processes which control and report the progress of the FEED. The following commentary gives the reader a brief guide to the project management process or approach which has been used. FEED Programme: In order to scope out, control and report the FEED activity, a Work Breakdown Structure was developed. This structure had the following hierarchy - Level 1 - Chain Element; Level 2 - Phase; Level 3 - Discipline; Level 4 - Work Package (including Cost Time Resource definition); The programme is in the form of a fully resource loaded, logically linked network diagram. Risk Management: Throughout this FEED the management of risk was a key activity. This has helped inform and better understand the important risks faced by the project. This 'first of a kind' project saw a large number of new risks being identified, assessed, controlled and monitored during FEED. Project Cost Estimates: An estimating philosophy was established in FEED to set the standards for the estimates produced from across the project participants, including: To ensure a consistent approach in the collection, calculation and presentation of costs across all FEED Participants; To ensure that all likely project costs are identified and captured along with all associated details. A standard template was established for each participant to complete with the details of their section (i.e. Chain Element) of the cost estimate. The cost estimate was broadly consistent with Class 3/4 estimate as defined by AACE. Further supporting documents for chapter 10 of the Key Knowledge Reference Book can be downloaded. Note this dataset is a duplicate of the reports held at the National Archive which can be found at the following link - http://webarchive.nationalarchives.gov.uk/20121217150421/http://decc.gov.uk/en/content/cms/emissions/ccs/ukccscomm_prog/feed/e_on_feed_/project_manage/project_manage.aspx

-

During 2010-11, as part of the Carbon Capture & Storage (CCS) Demonstration Competition process, E.ON undertook a Front End Engineering Design (FEED) study for the development of a commercial scale CCS demonstration plant at Kingsnorth in Kent, South East England. The study yielded invaluable knowledge and the resulting material is available for download here. This chapter is devoted to the transportation and injection infrastructure requirements of the Kingsnorth Carbon Capture and Storage development. This encompasses a 36 inch (outside diameter) pipeline which runs onshore for approx 10 km and offshore in the Southern North Sea for 260 km, a platform in the vicinity of the Hewett field location, and appropriate facilities both for the conditioning of CO2 before pipeline entry and the processing of the CO2 stream prior to injection into the sequestration site. The chapter highlights in particular the following areas:- Critical assumptions; Platform Concept Selection; Transport Solution Selection; Pipeline Key Issues; Pipeline Pre-Commissioning; Temperature; Emergency Shutdown; Personnel Safety; Venting; Flow Assurance Modelling. Throughout the execution of the work described in this chapter significant opportunity was taken to ensure that the interfaces from capture (and compression) to pipeline/platform and to wells/storage were managed closely. This was achieved by cross system interface management meetings organized to consider interface issues and to compare issues raised in separate HAZIDs. The purpose of conceptual design has been to identify the problems to be addressed comprehensively by the next stage of FEED and this suite of reports provides valuable insights to the challenges faced. All aspects of establishing an agreed philosophy for design and operation of a storage and transport system for CCS begin with understanding what the initial CO2 flow conditions will be at the interface between the well perforations and the reservoir (i.e. at the sandstone face at the bottom of the well). Further supporting documents for chapter 6 of the Key Knowledge Reference Book can be downloaded.

-

In March 2010, the Scottish CCS (Carbon Capture & Storage) Consortium began an extensive Front End, Engineering and Design (FEED) study to assess what would be required from an engineering, commercial and regulatory, perspective in order to progress the CCS demonstration project at Longannet Power station in Scotland through to construction. The study yielded invaluable knowledge and the resulting material are available for download here. This section of the report illustrates how the End-to-End CCS chain must be considered as a system as well as separate elements. It builds upon the description of the individual elements contained in Section 3, and captures the development of the End-to-End CCS chain design carried out during FEED. Specifically, this section focuses on the following aspects: Commissioning the system in preparation for operations, as well as decommissioning at the end of the capture and storage period; Operations and maintenance activities; Control; Metering and monitoring; Venting; This section also provides some selected information on the individual CCS chain elements and a summary of the RAM (reliability, availability and maintainability) analysis undertaken during FEED of which one of the key outputs was the anticipated CO2 injection profile for the project. The appropriate summary section from the Feed Close Out Report can be downloaded as a PDF (End to end CCS chain operation.pdf). The main text of the FEED Close Out Report, together with the supporting appendix for this section can be downloaded as PDF files. Note this dataset is a duplicate of the reports held at the National Archive which can be found at the following link - http://webarchive.nationalarchives.gov.uk/20121217150421/http://decc.gov.uk/en/content/cms/emissions/ccs/ukccscomm_prog/feed/scottish_power/ccs_chain/ccs_chain.aspx

BGS Data Catalogue

BGS Data Catalogue